- 2025-12-09 08:25

- Services

- Delhi

- 28 views

Location: Delhi

Price: Contact us

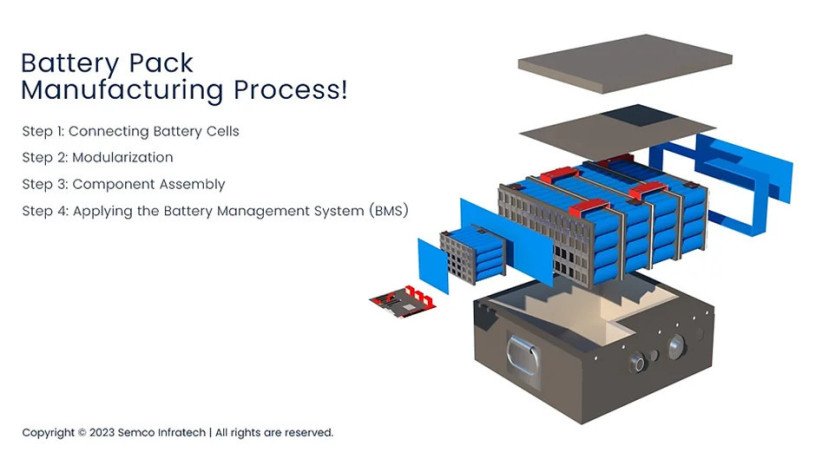

The most important stage in the production of any battery pack is connecting the battery cells. No matter how good the individual cells are, the entire pack becomes unreliable if the connections are weak, irregular, or misaligned. Current flow, pack durability, safety stability, and long-term performance are all determined at this stage. Manufacturers who approach it like a straightforward welding task typically experience unpredictable voltage drops, overheating problems, or failures.

The process demands precision: matching cells, aligning tabs, ensuring clean welds, and maintaining uniform electrical resistance across every connection. Modern production uses laser welding, ultrasonic welding, or automated bonding systems because manual methods simply can’t meet the accuracy required for EVs, ESS units, or high-power industrial applications.

At Semco Infratech, the approach to Connecting Battery Cells is designed for consistency. The goal isn’t to make connections that “work”—it’s to make connections that last through thousands of cycles. Stable joints, controlled heat dispersion, and minimal internal resistance are non-negotiable. This is what separates a dependable pack from one that fails prematurely.

![Myanmar [Burma]](https://adslynk.com/images/flags/circle/16/mm.png)